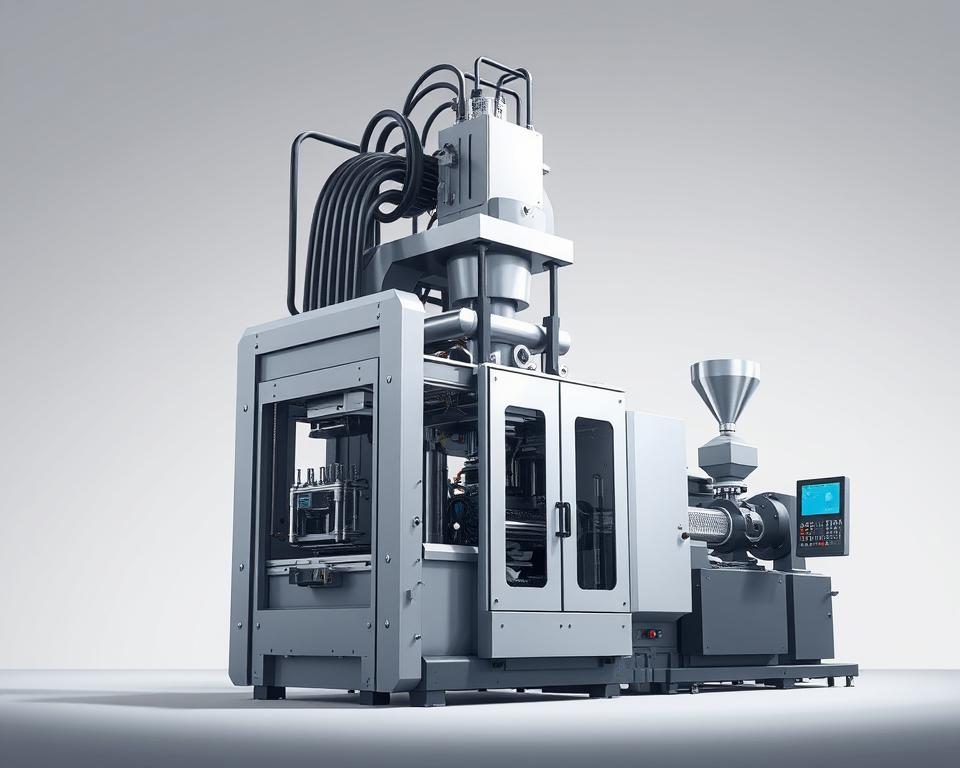

How to Find Reliable Injection Molding Services in China

Well, the major meeting has just concluded. your new project has the green light, time is pressing, and the budget is… well, let’s just say it’s tight.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Of course, you acknowledge. On paper, it’s logical. The potential savings can be massive. But your mind is already racing. You know the rumors, don’t you? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

But here’s the catch. Procuring plastic mold needn’t be a roll of the dice. It’s simply another project with clear steps. And as with any project, success depends on your methodology. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Forget the horror stories. Here’s a practical playbook to nail it.

First Things First: Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. You cannot expect overseas partners to interpret your unspoken requirements. Sending a vague request is like asking a builder to quote you for “a house.” The responses you get will be all over the map, and none of them will be useful.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. It’s the cornerstone of your entire effort.

What belongs in your RFQ?

First, your 3D CAD files. These are non-negotiable. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This serves as the definitive part geometry reference.

However, 3D alone won’t cut it. Include precise 2D engineering drawings. This is where you call out the stuff that a 3D model can’t communicate. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. Any seal surfaces or critical hole sizes must be clearly labeled.

Then specify the material. Avoid generic terms like “Plastic.” Don’t even just say “ABS.” Be specific. If you need SABIC Cycolac MG38 in black, say exactly that. Why? Because resin grades number in the thousands. Naming the precise grade locks in the mechanical, thermal, and aesthetic properties you need with what is plastic mold.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

Finally, include the business details. What’s your forecasted annual volume (EAU)? A supplier needs to know if they’re quoting a tool that will make 1,000 parts in its lifetime or 1,000,000 parts a year. Cavity count, tooling cost, and per-unit pricing depend on volume.

Finding the Right Supplier

With your RFQ perfected, now, who do you send it to? Online sourcing is global but crowded. Locating vendors is easy; vetting them is the real challenge.

Begin on popular marketplaces such as Alibaba or Made-in-China. They let you survey dozens of suppliers quickly. Treat them as initial research tools, not final solutions. Narrow your pool to about a dozen promising firms.

Still, you must dig deeper. Consider using a sourcing agent. Yes, they take a cut. Yet top agents deliver reliable, audited suppliers. They bridge language and cultural gaps. For a first-time project, this can be an invaluable safety net. Consider it timeline insurance.

Another tactic: trade exhibitions. If you can attend, shows such as Chinaplas transform sourcing. In-person meetings trump emails. Hold samples, talk shop, and gauge professionalism firsthand. Plus, ask peers for referrals. Ask other project managers in your network. Peer endorsements carry huge weight.

Separating Real Suppliers from Pretenders

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. estimates roll in. Some prices will undercut logic, others will shock you. Now, sift through and shortlist 2–3 reliable candidates.

How do you do that? It’s a bit of an art and a science.

First, look at their communication. Is their turnaround swift and concise? Is their English good enough for complex technical discussions? The true litmus: are they raising smart queries? A great supplier will review your RFQ and come back with thoughts. Example: “Should we add draft here for better ejection?” or “Your tolerance may require extended CMM time—okay?” That’s a huge positive sign. It shows they’re engaged and experienced. Anyone who simply agrees to all specs is a red flag.

Afterward, verify their technical arsenal. Ask for a list of their equipment. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. A small-gear shop won’t cut it for a big housing.

Then comes the audit. You can’t skip this. As you vet staff, you must vet suppliers. Either visit in person or engage a local audit service. They’ll send a local inspector to the factory for a day. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. It’s the best few hundred dollars you will ever spend on your project.

From Digital File to Physical Part

You’ve selected your partner. you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Then comes the real action.

The first thing you should get back after sending your payment is a DFM report. Design for Manufacturability (DFM) is essential. It’s their professional review of your CAD. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. Comprehensive DFM equals a top-tier supplier. It’s a two-way partnership. You work with their engineers to refine the design for optimal production.

Once the DFM is approved, they’ll start cutting steel to make your injection mold tool. In a few weeks, you’ll see “T1 samples are on the way.” These represent the first trial parts. It’s your test of success.

T1 parts usually require adjustments. That’s standard process. There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You supply feedback, they tweak the tool, and T2 plastic mold samples follow. This process might take a couple of rounds. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

At last, you get the perfect shot. It matches all specs, has a pristine finish, and works as required. This is your golden sample. You sign off, and it serves as the master quality reference.

Completing the Sourcing Journey

Landing the golden sample is huge, yet the project continues. Now you’re entering the mass production phase. How do you maintain consistency for part 10,000?

Implement a robust QC plan. This often involves a pre-shipment inspection. Use a third-party inspector again. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. They provide a photo-filled inspection report. After your approval, you release the shipment and final funds. This simple step prevents you from receiving a container full of scrap metal.

Lastly, plan logistics. Understand the shipping terms, or Incoterms. Does FOB apply, passing risk at the ship’s rail? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? These choices hugely affect landed cost.

Sourcing from China is a marathon, not a sprint. It hinges on strong supplier relations. See them as collaborators, not vendors. Transparent dialogue, respect, and process discipline win. No question, it’s demanding. However, armed with this guide, you’ll secure savings and keep high standards intact. You’re set to succeed.